The

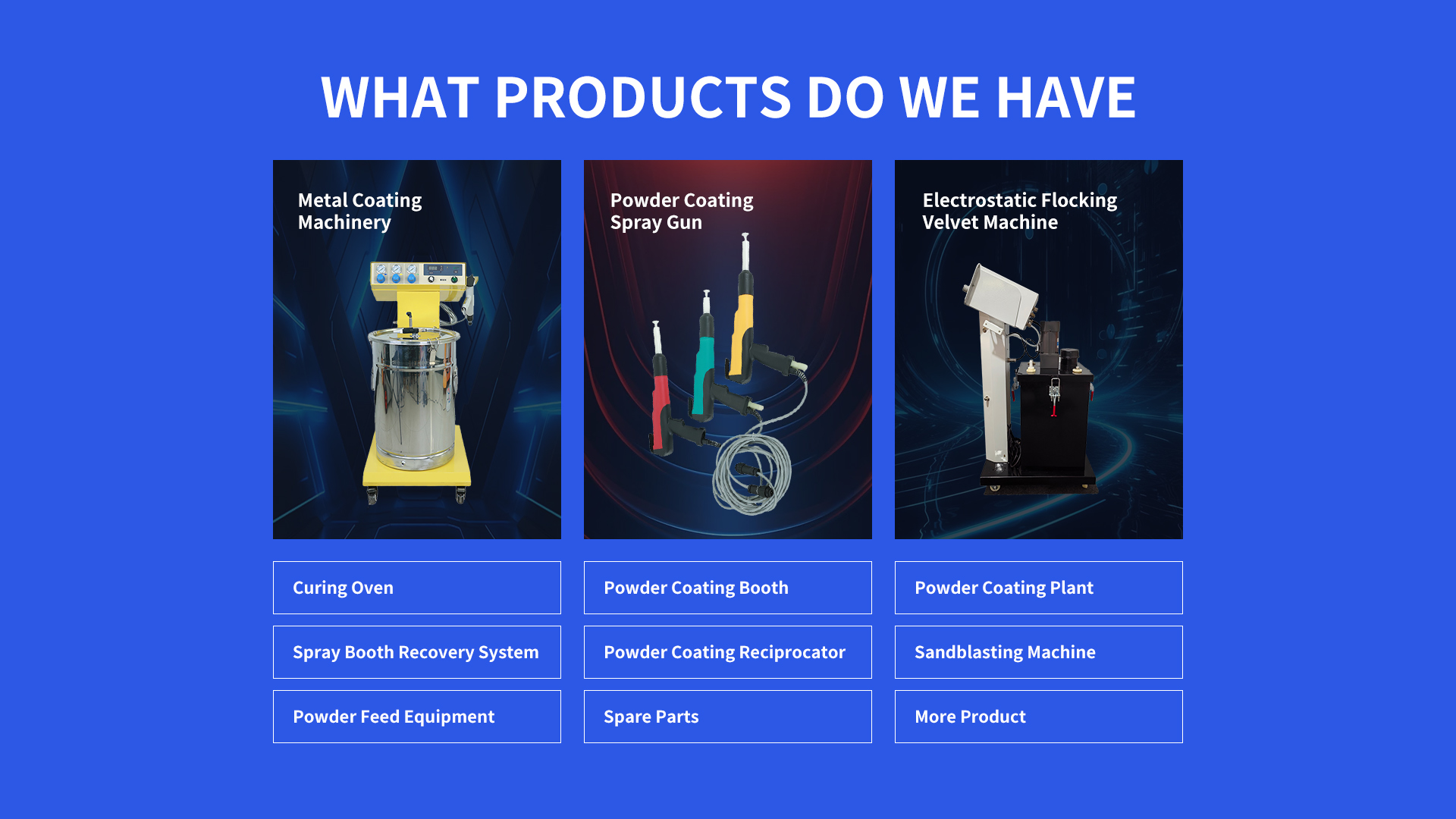

Powder Coat Machine is a cornerstone in the coating industry, revolutionizing the way surfaces are protected and adorned. This machine is designed to apply powder coatings, which offer numerous advantages over traditional liquid paints.

At its core, the

Powder Coat Machine consists of key components. The powder hopper stores the powder coating material, while the powder feeder regulates its flow to the spray gun. The spray gun, a crucial part, electrostatically charges the powder particles as they exit. This charge causes the powder to be attracted to the grounded workpiece, ensuring a uniform and efficient coating.

The working principle of the

Powder Coat Machine is based on electrostatic attraction. As the charged powder leaves the spray gun, it is drawn to the workpiece, creating a thin layer. After application, the coated workpiece is cured in an oven. Heat causes the powder particles to melt, flow, and bond together, forming a durable, smooth finish.

Powder Coat Machines have a wide range of applications. In the automotive industry, they are used to coat car bodies, providing corrosion resistance and an attractive appearance. The furniture industry benefits from these machines as well, using them to coat wooden and metal furniture for enhanced durability and aesthetic appeal. In the construction sector, Powder Coat Machines are employed to coat metal structures like fences and railings, protecting them from the elements.

When operating a

Powder Coat Machine, proper preparation is key. The workpiece must be clean, free from dirt, oil, and rust. Adjusting the machine settings, such as powder flow rate and electrostatic voltage, according to the workpiece's size, shape, and the type of powder, is essential for achieving the desired coating quality.

Maintenance of the

Powder Coat Machine is equally important. Regularly clean the powder hopper, spray gun, and other components to prevent powder buildup. Check and replace worn - out parts like the spray gun nozzle periodically. Calibrate the electrostatic generator and other sensors to ensure accurate operation. By following these guidelines, users can maximize the performance and lifespan of their Powder Coat Machine, achieving high - quality coatings consistently.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com